FY-SLT42

FY LIGHTING

| Availability: | |

|---|---|

| Quantity: | |

Specification

Power |

1000/1500/2000/3000W |

Battery |

10/15/20/25AH |

Solar panel |

10/15/20/30W |

Working time |

12-36H |

Charging time |

5-8H |

Working mode |

Light control + remote control |

Luminous |

576/1224/2160/5088LM |

Light source |

96/204/360/1272PCS |

Lamp size |

500*210*70mm |

Pole |

φ60CM with 50CM long |

Packaging |

61*38.5*13.5CM 61*38*15CM (3000W) |

G.W |

3.5/4.3/5/6.8 KG |

Warranty |

2 years |

What is the difference between IP65 and IP66?

The main difference in waterproof effect between IP66 and IP65 is that IP66 has a higher waterproof level.

The IP66 lighting fixtures are completely resistant to external intrusion, can completely prevent dust from entering, and can withstand strong wave impacts or strong water spray, while the water intake of electrical appliances does not reach harmful effects. By contrast, IP65 is typically suitable for outdoor environments and can withstand slight water exposure such as rain.

Overall, IP66 has a higher waterproof rating and is more suitable for more harsh environments such as being washed away by water, wave impact, etc. In addition, the waterproof tests for IP66 and IP65 are also different. The testing of IP66 includes continuously withstanding strong water currents to ensure that electrical equipment can still operate normally at a certain depth underwater for a long time. IP65, on the other hand, mainly focuses on its ability to prevent splashing and short-term immersion in water.

In practical applications, it is necessary to choose the appropriate waterproof level based on the usage environment and requirements. For electrical equipment that needs to be used outdoors or in humid environments for a long time, it is recommended to choose equipment with an IP66 or higher waterproof rating to ensure the normal operation and safety of the equipment.

Why is aluminum shell more durable than plastic shell in the application scenarios of solar street lights?

Aluminum shell has stronger corrosion resistance: Aluminum is a metal that is not easily corroded and can maintain its original appearance and performance for a long time. In contrast, plastic shells are easily affected by environmental factors such as ultraviolet radiation, humidity, and chemicals, and long-term use can lead to aging, discoloration, cracking, and other phenomena.

Aluminum shell has better thermal stability: Aluminum has good thermal conductivity, which can effectively dissipate the heat generated by the street lamp during operation, thereby avoiding damage to the lamp caused by overheating. Meanwhile, the aluminum shell is not easily deformed during temperature changes and can maintain good structural stability.

Aluminum shell has higher mechanical strength: Aluminum shell has a certain degree of rigidity and strength, can withstand a certain degree of pressure and impact, and is not easily deformed or damaged. In contrast, plastic shells have lower mechanical strength and are easily damaged by external forces.

Aluminum shell has a longer lifespan: Due to its good corrosion resistance, thermal stability, and mechanical strength, its service life is relatively long. Even under harsh environmental conditions, aluminum shells can maintain long-term stability performance.

In summary, in the application scenarios of solar street lights, aluminum shells are more durable than plastic shells. In addition to the reasons mentioned above, the application of aluminum shells in solar street lights has other advantages. For example, aluminum casing has good electrical performance, which can effectively isolate the internal circuits and external environment of the lamp, ensuring the safe use of the lamp. In addition, aluminum shells are easy to process and manufacture, and can be customized according to different needs, with high production efficiency and economic benefits.

In contrast, plastic casings have certain limitations in certain aspects. For example, plastics are prone to aging due to the influence of ultraviolet radiation, and long-term use can lead to problems such as embrittlement and discoloration. In addition, the thermal conductivity of plastics is poor, which is not conducive to the heat dissipation of lamps, and long-term use may have adverse effects on the performance of lamps.

Therefore, in the application scenarios of solar street lights, aluminum shells are more durable than plastic shells. Choosing aluminum shell as the shell material for solar street lights can improve the service life and performance of the lights, reduce maintenance costs, and have good environmental and economic performance.

While aluminum casing comes so many benefits, we still need to consider other factors during purchase and selling:

End customers' using scenarios

End customers' demand of use

End customers' budget

Your profit of selling

etc.

Plastic casing solar street lights are still the best selling and most using type in 2024.

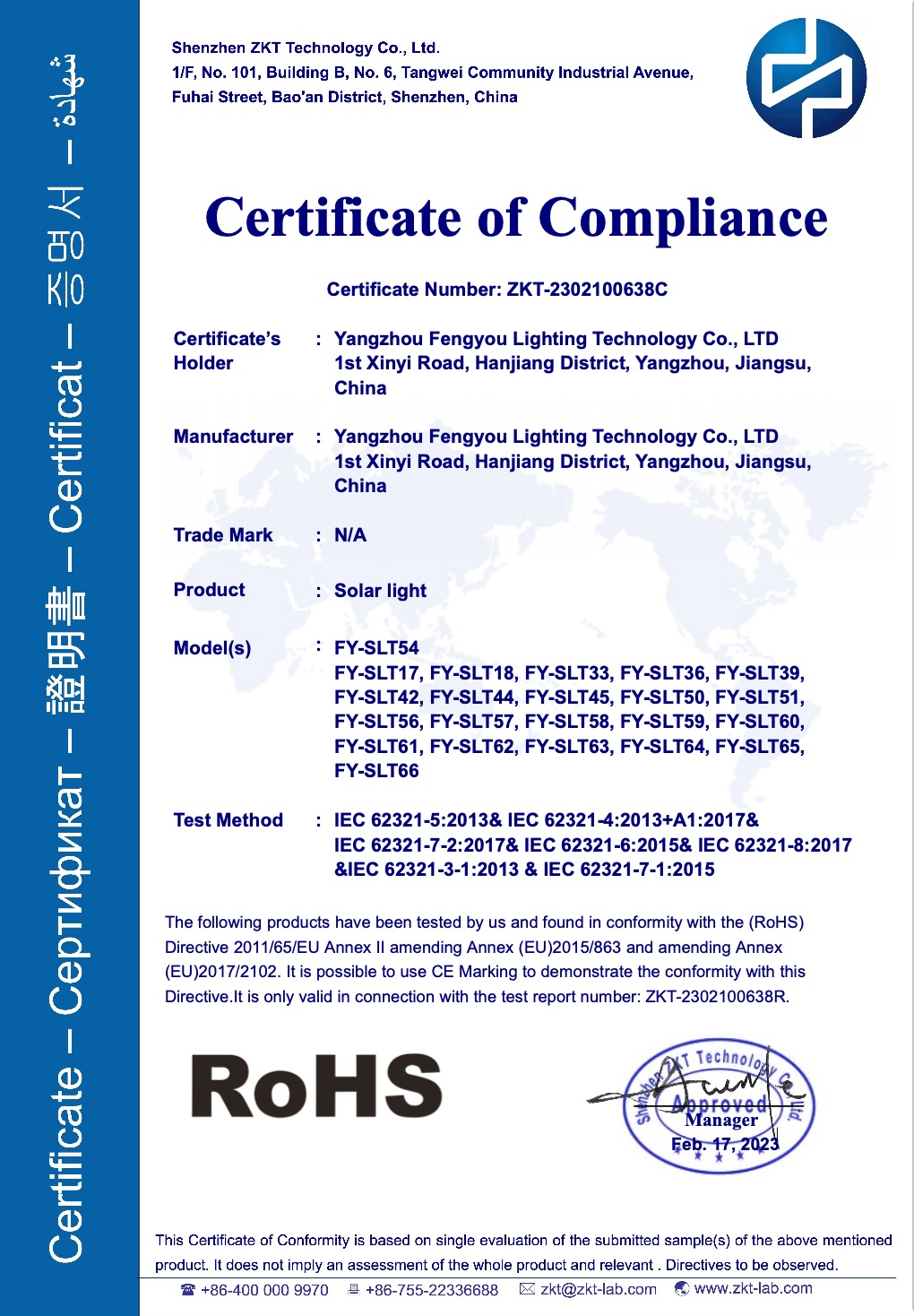

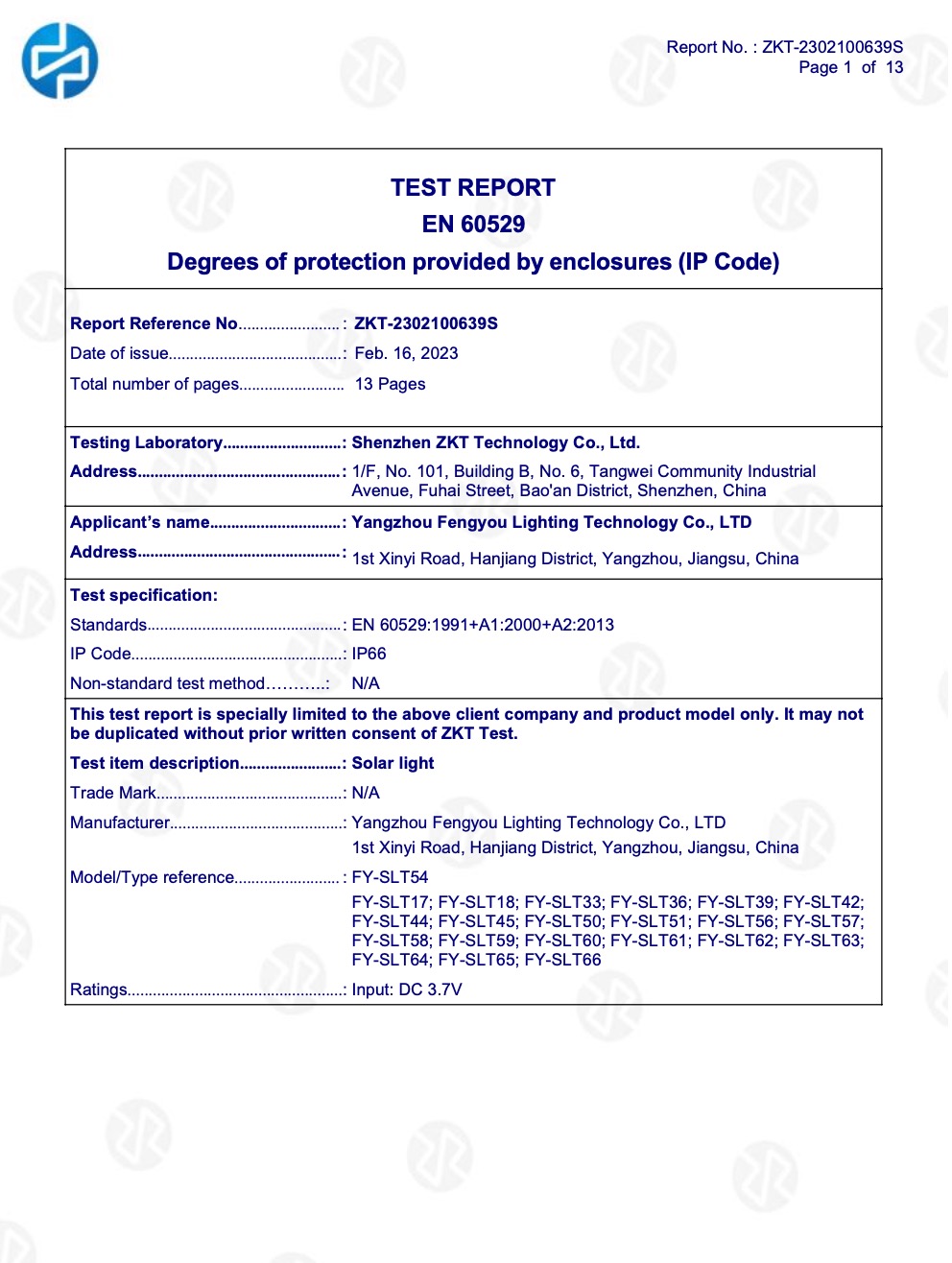

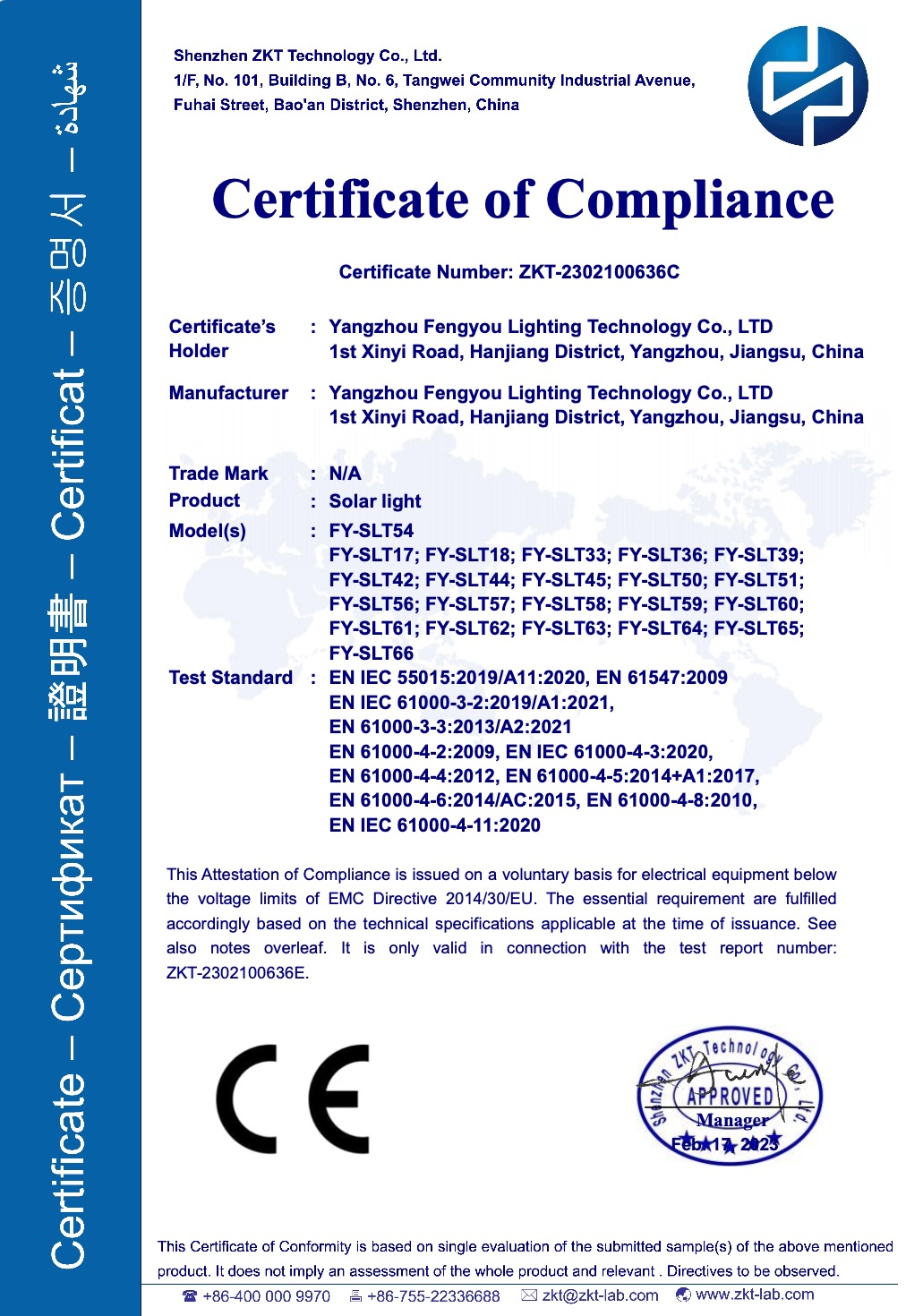

IP66 CERTIFICATE

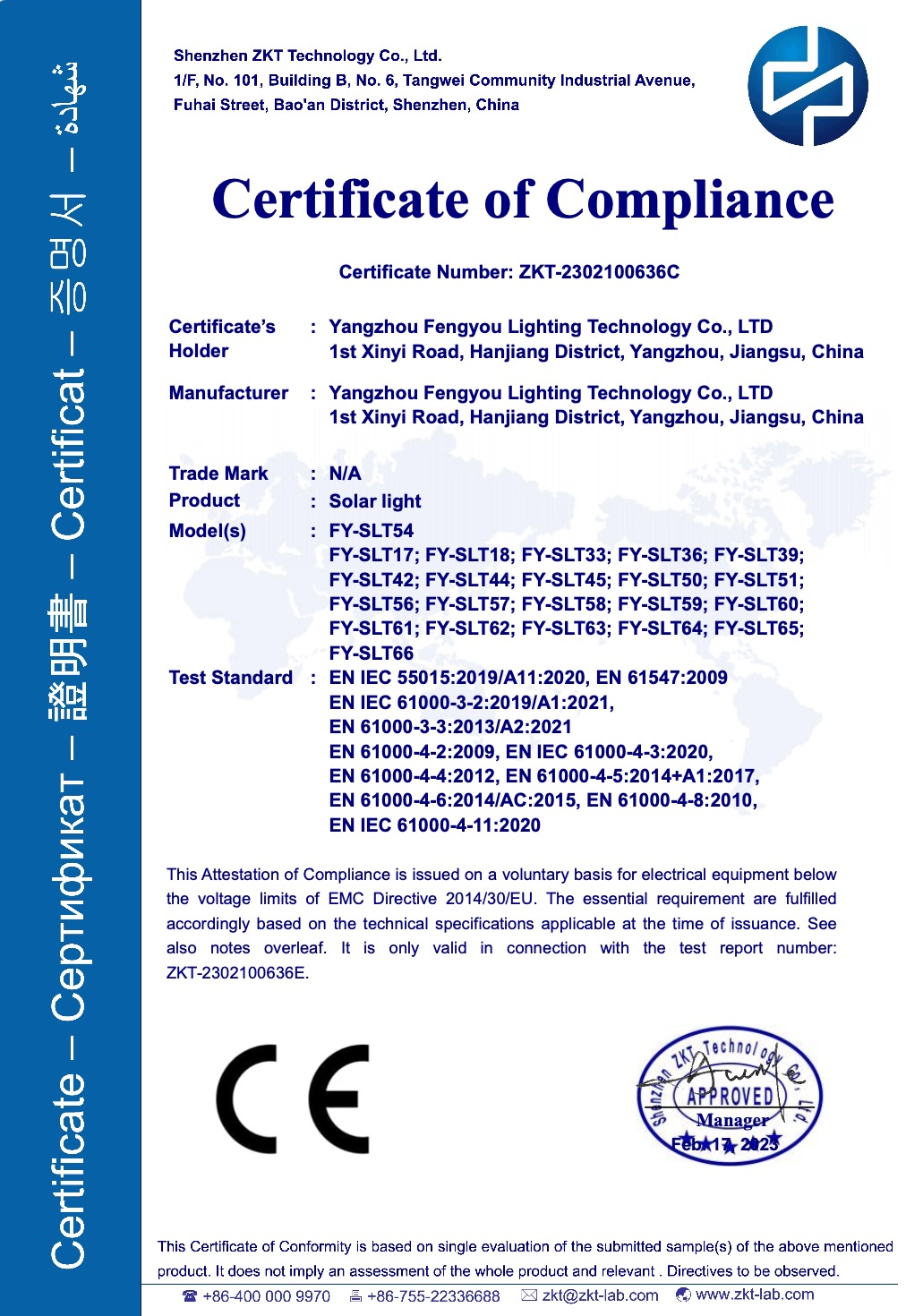

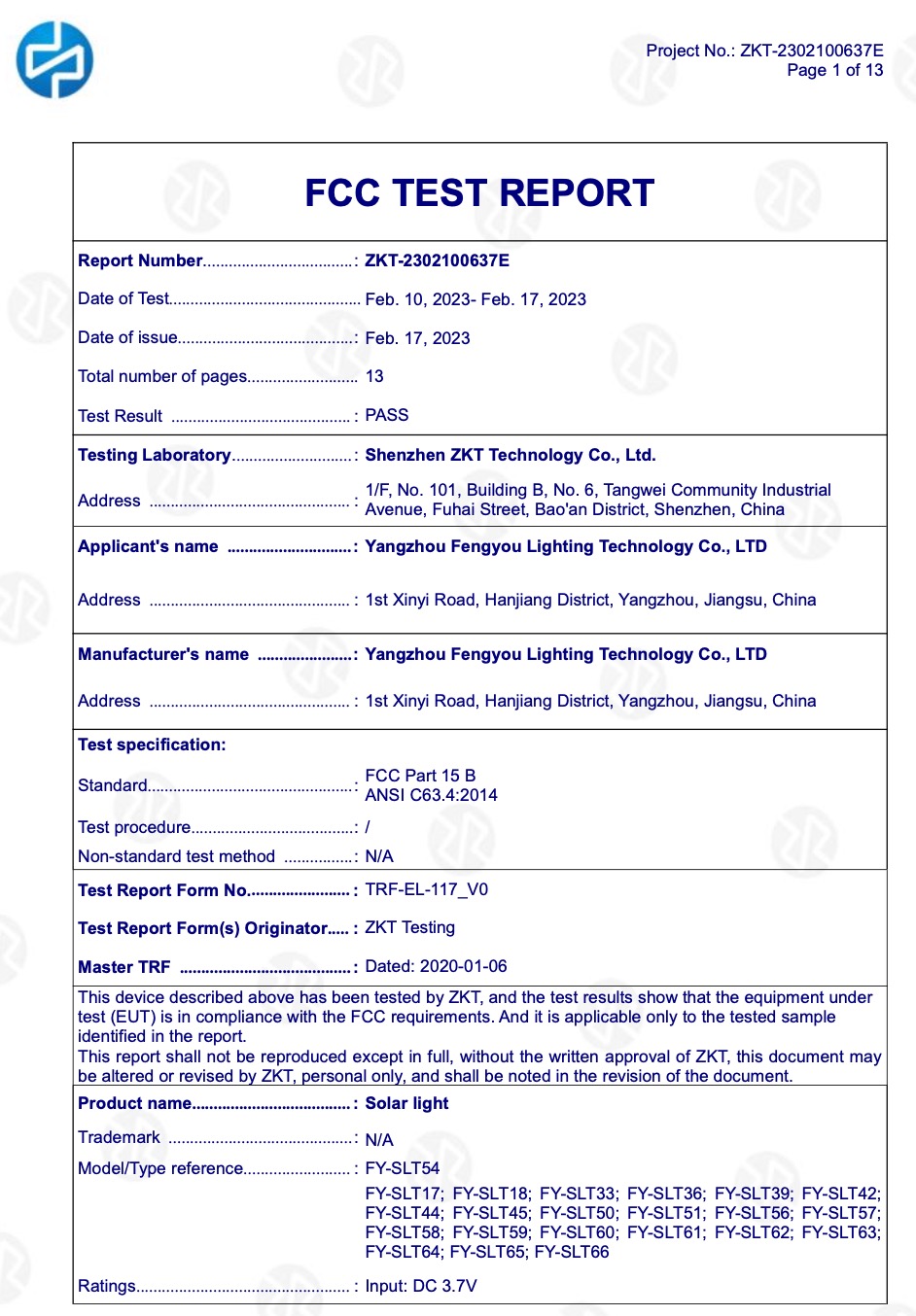

FCC CERTIFICATE

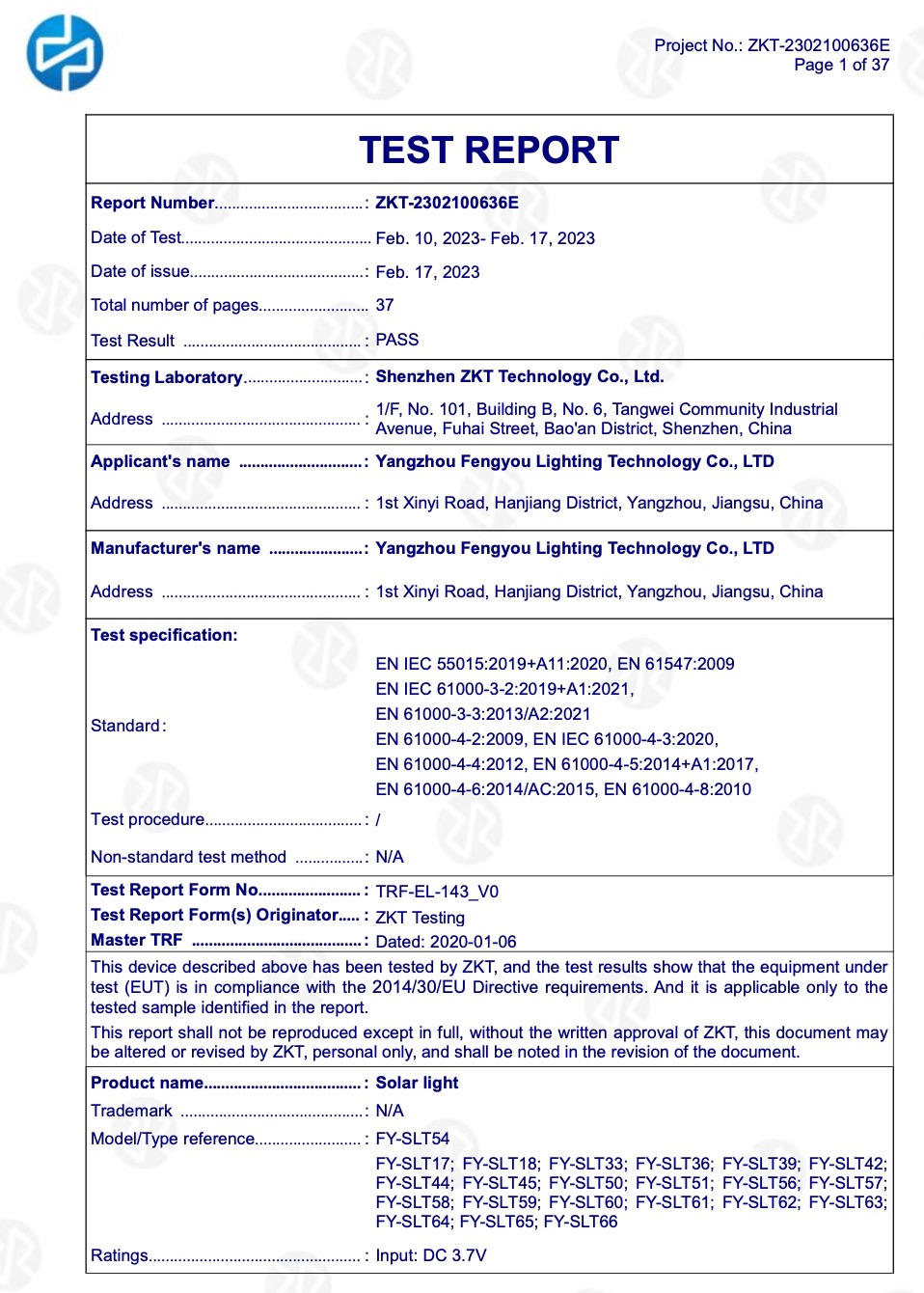

CE CERTIFICATE

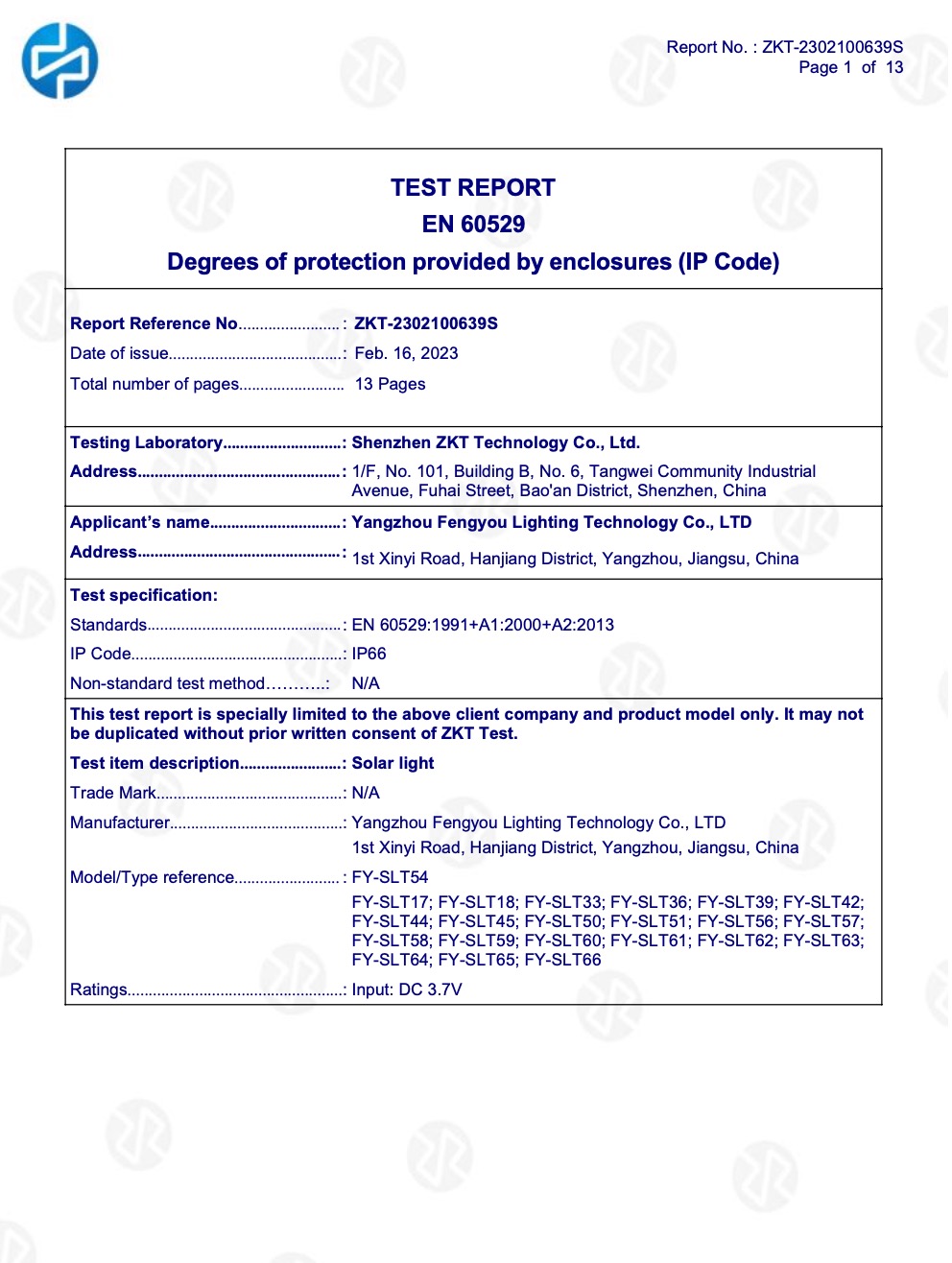

IP66 REPORT

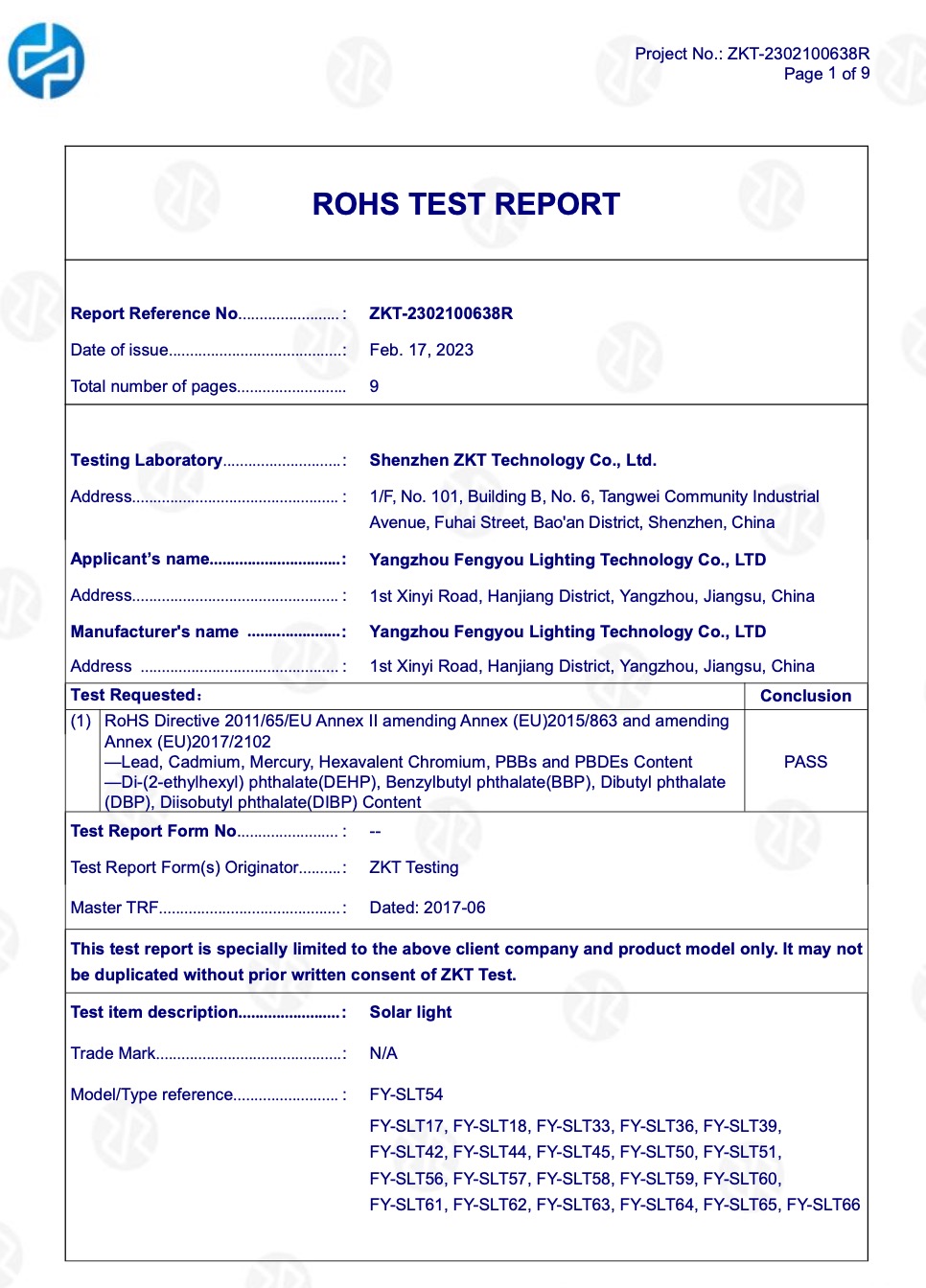

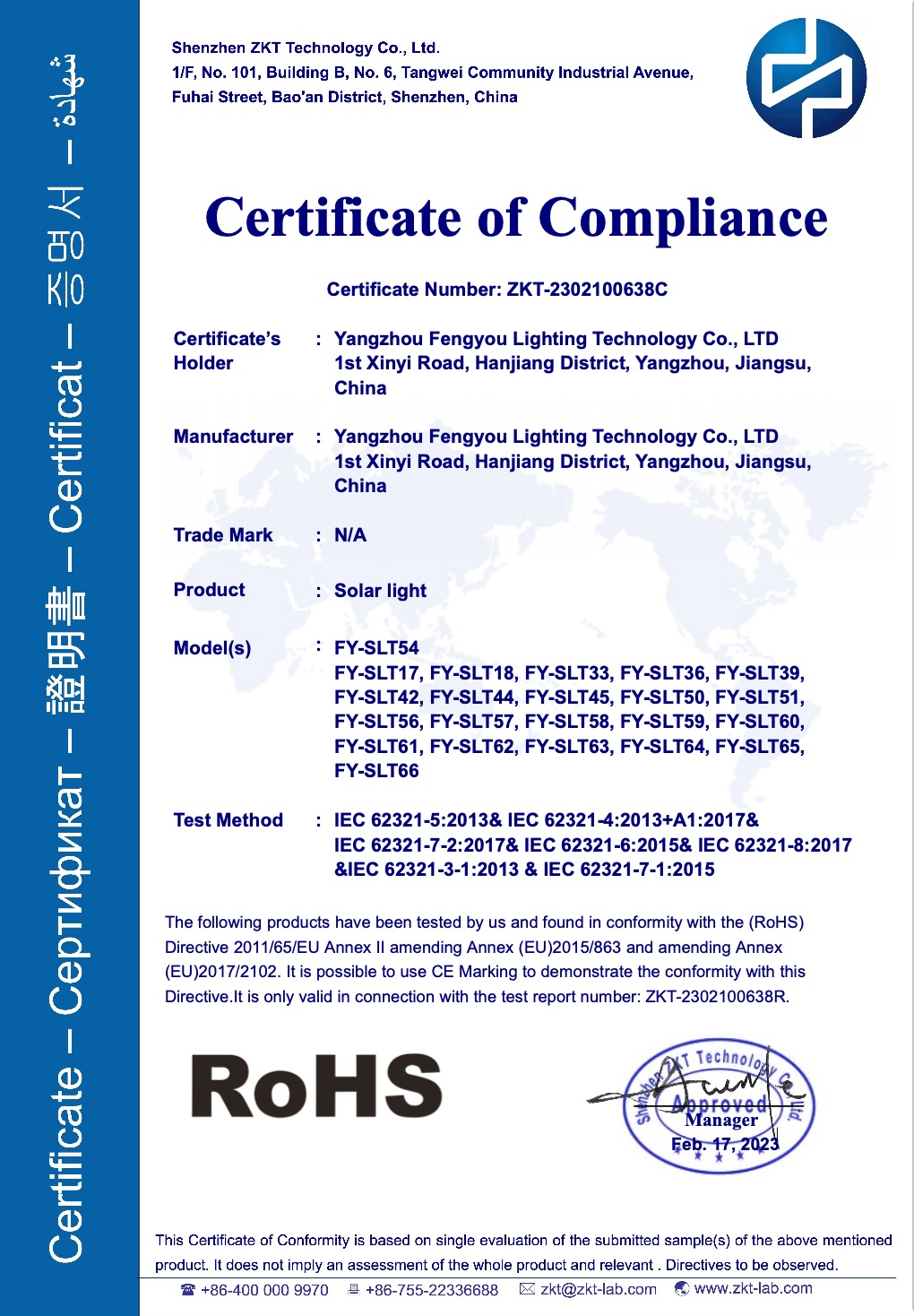

ROHS REPORT

FCC REPORT

CE REPORT

TUV-1

TUV-2

SGS-1

SGS-2

Specification

Power |

1000/1500/2000/3000W |

Battery |

10/15/20/25AH |

Solar panel |

10/15/20/30W |

Working time |

12-36H |

Charging time |

5-8H |

Working mode |

Light control + remote control |

Luminous |

576/1224/2160/5088LM |

Light source |

96/204/360/1272PCS |

Lamp size |

500*210*70mm |

Pole |

φ60CM with 50CM long |

Packaging |

61*38.5*13.5CM 61*38*15CM (3000W) |

G.W |

3.5/4.3/5/6.8 KG |

Warranty |

2 years |

What is the difference between IP65 and IP66?

The main difference in waterproof effect between IP66 and IP65 is that IP66 has a higher waterproof level.

The IP66 lighting fixtures are completely resistant to external intrusion, can completely prevent dust from entering, and can withstand strong wave impacts or strong water spray, while the water intake of electrical appliances does not reach harmful effects. By contrast, IP65 is typically suitable for outdoor environments and can withstand slight water exposure such as rain.

Overall, IP66 has a higher waterproof rating and is more suitable for more harsh environments such as being washed away by water, wave impact, etc. In addition, the waterproof tests for IP66 and IP65 are also different. The testing of IP66 includes continuously withstanding strong water currents to ensure that electrical equipment can still operate normally at a certain depth underwater for a long time. IP65, on the other hand, mainly focuses on its ability to prevent splashing and short-term immersion in water.

In practical applications, it is necessary to choose the appropriate waterproof level based on the usage environment and requirements. For electrical equipment that needs to be used outdoors or in humid environments for a long time, it is recommended to choose equipment with an IP66 or higher waterproof rating to ensure the normal operation and safety of the equipment.

Why is aluminum shell more durable than plastic shell in the application scenarios of solar street lights?

Aluminum shell has stronger corrosion resistance: Aluminum is a metal that is not easily corroded and can maintain its original appearance and performance for a long time. In contrast, plastic shells are easily affected by environmental factors such as ultraviolet radiation, humidity, and chemicals, and long-term use can lead to aging, discoloration, cracking, and other phenomena.

Aluminum shell has better thermal stability: Aluminum has good thermal conductivity, which can effectively dissipate the heat generated by the street lamp during operation, thereby avoiding damage to the lamp caused by overheating. Meanwhile, the aluminum shell is not easily deformed during temperature changes and can maintain good structural stability.

Aluminum shell has higher mechanical strength: Aluminum shell has a certain degree of rigidity and strength, can withstand a certain degree of pressure and impact, and is not easily deformed or damaged. In contrast, plastic shells have lower mechanical strength and are easily damaged by external forces.

Aluminum shell has a longer lifespan: Due to its good corrosion resistance, thermal stability, and mechanical strength, its service life is relatively long. Even under harsh environmental conditions, aluminum shells can maintain long-term stability performance.

In summary, in the application scenarios of solar street lights, aluminum shells are more durable than plastic shells. In addition to the reasons mentioned above, the application of aluminum shells in solar street lights has other advantages. For example, aluminum casing has good electrical performance, which can effectively isolate the internal circuits and external environment of the lamp, ensuring the safe use of the lamp. In addition, aluminum shells are easy to process and manufacture, and can be customized according to different needs, with high production efficiency and economic benefits.

In contrast, plastic casings have certain limitations in certain aspects. For example, plastics are prone to aging due to the influence of ultraviolet radiation, and long-term use can lead to problems such as embrittlement and discoloration. In addition, the thermal conductivity of plastics is poor, which is not conducive to the heat dissipation of lamps, and long-term use may have adverse effects on the performance of lamps.

Therefore, in the application scenarios of solar street lights, aluminum shells are more durable than plastic shells. Choosing aluminum shell as the shell material for solar street lights can improve the service life and performance of the lights, reduce maintenance costs, and have good environmental and economic performance.

While aluminum casing comes so many benefits, we still need to consider other factors during purchase and selling:

End customers' using scenarios

End customers' demand of use

End customers' budget

Your profit of selling

etc.

Plastic casing solar street lights are still the best selling and most using type in 2024.

IP66 CERTIFICATE

FCC CERTIFICATE

CE CERTIFICATE

IP66 REPORT

ROHS REPORT

FCC REPORT

CE REPORT

TUV-1

TUV-2

SGS-1

SGS-2